|

Achievements - Stage II

The achievements in the second stage of the project were:

- Acquisition of a dual laser scanning system for medium and large objects with the following specifications: laser output: max 1mW, class II, wavelength: 650-700 nm (visible red), laser ray dispersion: passive optical, uniform dispersion, without moving parts; standoff distance: min 100 mm max 200 mm; visual depth of field: min 170 mm, scan line length: min 25mm max 50mm; per-point accuracy: up to 25 µm with averaging; line resolution: 480 points/line; sampling rate with full field of view activated: min. 20 000 points / sensor/ second, min. 40 000 total points/second. Mechanical coupling of 3D scanning sensor with the 6-DOF industrial robot. Implementation of software modules for interfacing and synchronizing between the data acquisition software of the laser sensor and the robot controller and the rotary table controller. Motion planning implementation for robot + rotary table 7-DOF system, with collision and singularity avoidance and restrictions over speed and acceleration of the rotary table.

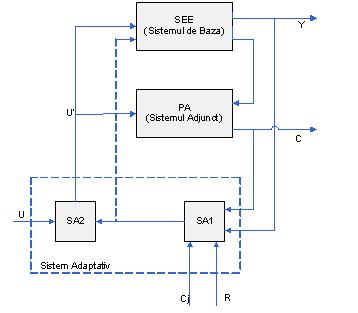

- Instalarea unui sistem de achizitie de date si monitorizare a procesului de frezare. Folosirea unui sistem adaptiv de control pentru masina unealta. Definirea algoritmului de optimizare neliniara a procesului de aschiere. Proiectarea unui modul care permite modificarea parametrilor tehnologici precum viteza de avans si de rotatie in timp real, la valori diferite de cele prescrise de programul masinii.

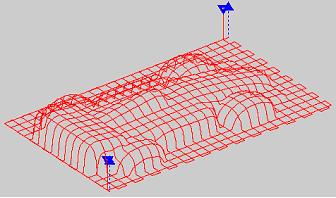

- Implementation of the error reduction algorithms acquired from 3D scanning sensor. Implementation of the algorithms for depth map surface representation. Morphological operations for depth maps used for CNC milling trajectory generation.

3D scanning simulation for the interior of a mould.

For technical details, please see:  ICCC 2008 Paper (PDF) ICCC 2008 Paper (PDF)

click to play

Technical documentation for stage II Technical documentation for stage II

Delivered results

- Technical and economical documentation for equipment acquisition

- Technical project

- Specifications for expected achievements

- Technical project

- Technical specification for the adaptive machining module

- Technical project

- Physical model of the mounting device for the 3D sensor

- Algorithms and implementations for robot motion control

- Scientific report

- Algorithms and software system for 3D reconstruction of object models

- Scientific research report

- Performance study

- Scientific research report

- Algorithms and conversion techniques for SI units

- Algorithms and software for grayscale morphological image operations

|