|

Achievements - Stage IV

Adaptive control strategies for milling process optimization

For technical details, please see:

IMS 2010 Paper (PDF) IMS 2010 Paper (PDF)

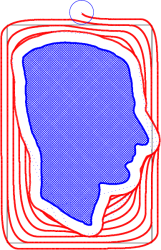

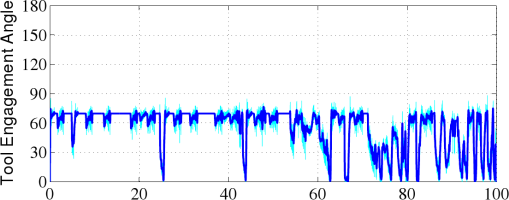

Adaptive Milling Toolpaths with Tool Engagement Angle control

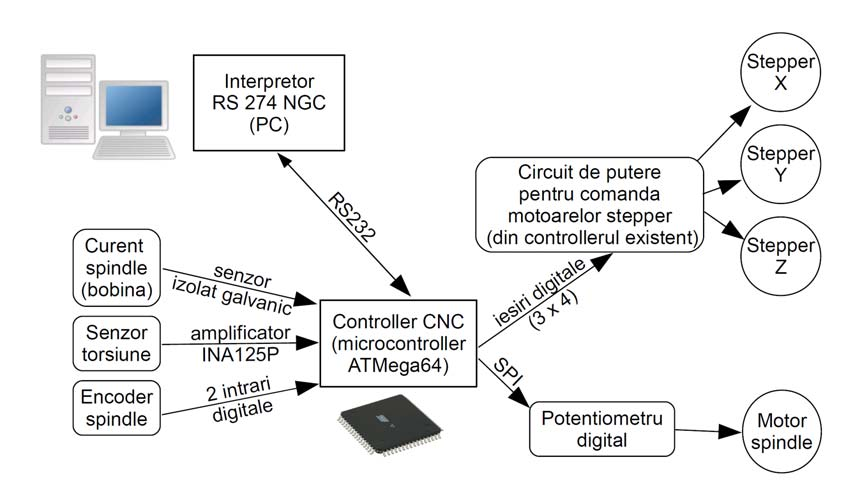

Adaptive control architecture for EMCO F1 CNC milling machine

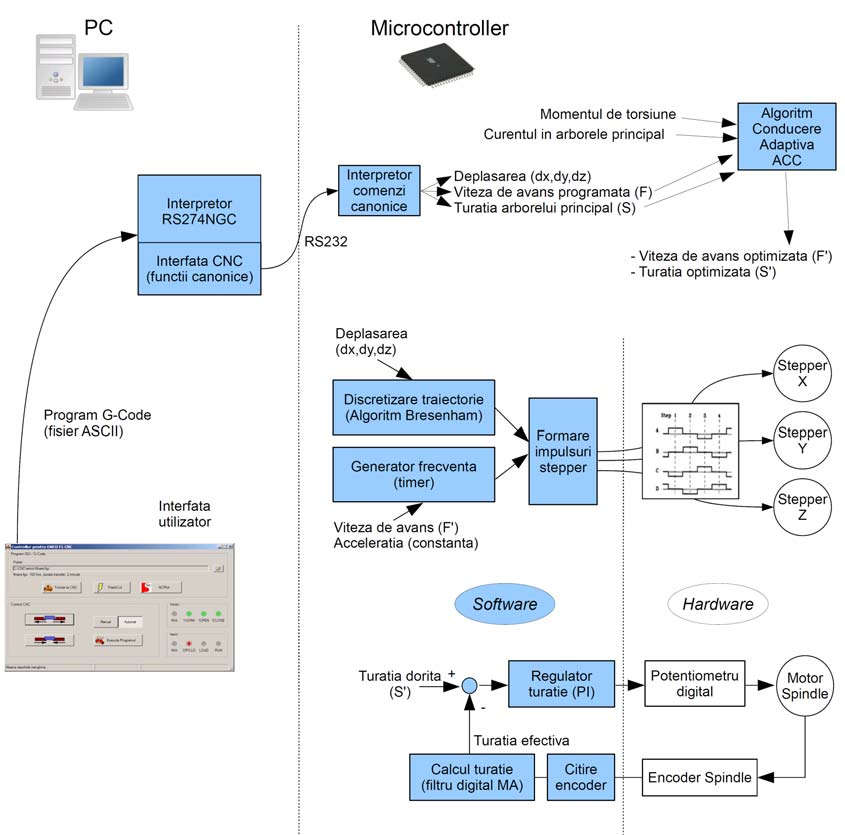

Proposed hardware architecture contains the following components:

- PC workstation

- 8-bit microcontroller: ATMega64

- Spindle current sensor: CUIINC SCD05PUR, range ±5A, with galvanic isolation

- Torque sensor for spindle: INTERFACE TS19 - Wheatstone bridge, range 0-100 Nm, with 0-15 mV output at 10V DC power supply

- Signal amplifier: Burr-Brown INA125P (gain factor: 100)

- Rotation sensor for main spindle: quadrature incremental encoder, CUIINIC MAG30

- Digital variable resistor, Microchip MCP41050

- Power circuits for actuating stepper motors (from the existing EMCO F1 CNC controller)

Softare components are divided in two categories:

Softare components are divided in two categories:

- Software which runs on the PC

- Graphical user interface

- G-Code interpreter for RS274/NGC

- Software which runs on the microcontroller

- G-Code command interpreter

- ACC adaptive control algorithm

- Pulse generator for X/Y/Z stepper motors

- Feedback control loop for main spindle

Technical documentation for stage IV Technical documentation for stage IV

Delivered results

- Scientific research report

- Testing and experiments report

- Technical study

- Research report about adaptive CNC machining

- Patent application submitted to Romanian State Office for Inventions and Trademarks (OSIM)

Title (translated): Method, Apparatus and Software Solution for Complete and Exact 3D Digital Description of Complex Surfaces by Robot Scanning and Milling Toolpath Generation from Depth Map Representations

|